Factory of the Future

Augmented Reality is a powerful new technology with already proven advantages for manual assembly tasks. For this project, an AR app for the Microsoft HoloLens was developed and tested against alternative app designs on a mobile tablet.

Problem Statement

Augmented Reality interfaces are a relatively new field of interaction design. Little research has been done to identify the best ways to design AR applications and the usability of these devices in specific contexts is still unknown. This work, commissioned by Boeing, sought to understand how best to display AR instructions to the user in a factory environment, and which hardware device is best for presenting the information.

Demonstration of the HoloLens AR application

App Development

During the course of this research, two AR applications were built to provide mock aircraft wing assembly instructions, one created for a mobile tablet and the other for the Microsoft HoloLens. The tablet application was used to compare different interface elements for providing navigation cues to a user in a factory environment. The HoloLens application allowed the user to operate hands-free and was tested for efficiency and accuracy in comparison to the tablet version.

A/B Testing

Data was collected through a user study featuring a between subjects design to determine which UI best provided navigational cues in AR. Users performed the assembly task using one of the three UI conditions. The three different navigation methods were tested were a 3D arrow to point towards the desired location, floating gates (like you might see in a video game), and a Point of Interest map. The tasks were accompanied by a demographic survey, a spatial thinking test, and a qualitative post-questionnaire. Metrics like duration, and number of errors was also measured. The results showed that the 3D gates navigation method helped users perform the task more efficiently than the other methods.

Tablet AR application

Usability Testing

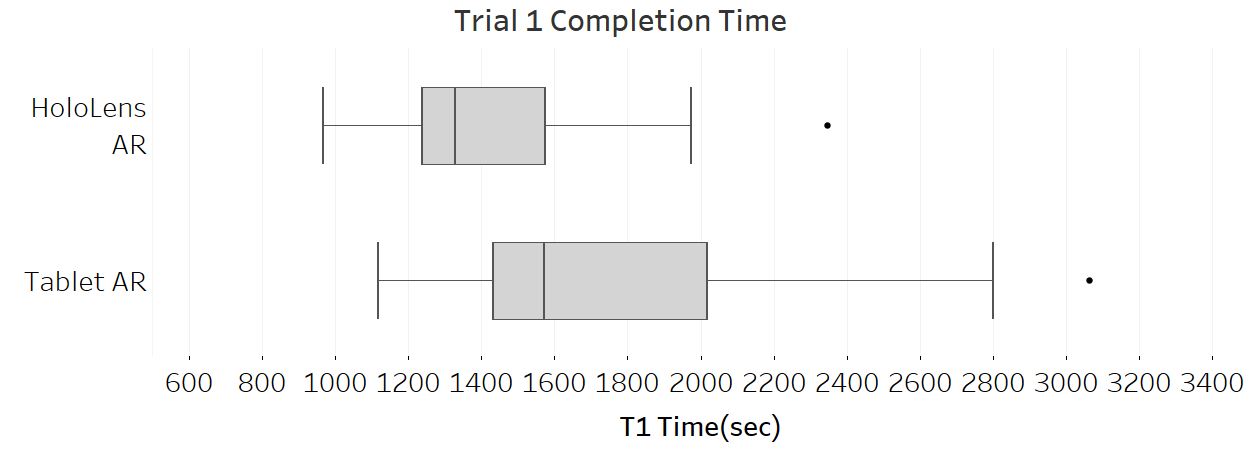

Next we tested the effects of of using a head-mounted AR display on assembly speed and accuracy to determine if these devices are a viable option for delivering manufacturing instructions. Qualitative feedback regarding the overall user experience of the system were also recorded using a survey. 75 participants completed a mock wing assembly task using either the Microsoft HoloLens (n=35) or the AR tablet (n=40). A Kruskal-Wallis H test showed that participants completed the assembly faster when using the Microsoft HoloLens. However, some participants found the device uncomfortable to wear and thought it impeded their vision at times.

Results

At the end of this project, my team and I were able to recommend the Microsoft HoloLens as a viable product for delivering AR work instructions to manufacturing staff at Boeing. We were also able to outline key interface elements, such as using 3D gates for navigation. Lastly, we recommended that work instructions for the Microsoft HoloLens include features that enable the user to toggle the AR content on and off to reduce distractions when performing certain tasks.

Lessons Learned

This project was challenging because of the lack of previous research on user interfaces in AR. The process of developing this application required a lot of iterative testing in order to create a viable product. I learned that testing early and often is essential to new product development, especially in AR.